Exploring the technology, processes, and global industrial equipment that drive modern precision manufacturing of robust industrial components.

Precision manufacturing represents the pinnacle of engineering accuracy, where components are produced with extremely tight tolerances, often measured in micrometers. This level of precision is essential for industries ranging from aerospace and medical devices to automotive and electronics, where even the smallest deviation can compromise performance, safety, or functionality.

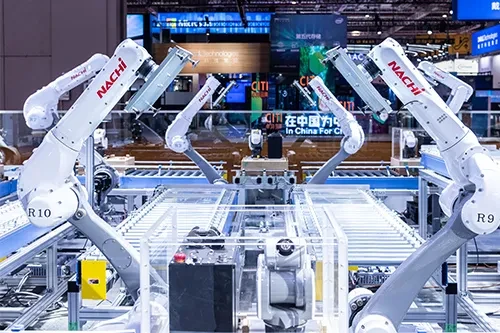

At the heart of this sophisticated production process lies a diverse array of specialized industrial equipment. These machines, often integrated into complex manufacturing systems, transform raw materials into highly precise components through a combination of cutting-edge technology, advanced materials science, and meticulous process control. Global industrial equipment manufacturers continuously innovate to meet the ever-increasing demands for higher precision, greater efficiency, and enhanced versatility.

The evolution of precision manufacturing has been closely tied to advancements in industrial equipment. From the earliest lathes and milling machines to today's computer numerical control (CNC) systems and additive manufacturing technologies, each innovation has expanded the possibilities of what can be produced with precision. Global industrial equipment networks now enable the standardization and distribution of these advanced manufacturing capabilities across international supply chains.

Unlike conventional manufacturing, which focuses primarily on producing functional parts at scale, precision manufacturing emphasizes dimensional accuracy, surface finish, material integrity, and repeatability. This requires not only specialized equipment but also a comprehensive understanding of materials behavior, machine dynamics, and measurement science. Global industrial equipment providers play a crucial role in developing and disseminating this knowledge alongside their machinery offerings.

Applications of Precision Manufacturing

Precision manufacturing techniques power countless critical industries, each with unique requirements that drive innovation in global industrial equipment design and capabilities.

Aerospace & Defense

Aerospace components demand exceptional precision to ensure safety, performance, and fuel efficiency. Turbine blades, structural components, and avionics all rely on advanced manufacturing processes.

Global industrial equipment used in this sector must meet stringent certification standards while handling exotic materials like titanium alloys and composites.

Medical Devices

From surgical instruments to implantable devices, medical manufacturing requires exceptional precision and material purity. Components often feature complex geometries tailored to individual patients.

Global industrial equipment in medical manufacturing must adhere to strict regulatory requirements and maintain sterile production environments.

Automotive

Modern vehicles rely on thousands of precision components, from engine parts and transmissions to sensors and safety systems. Tolerances directly impact performance, emissions, and reliability.

Global industrial equipment for automotive manufacturing balances high precision with the need for mass production capabilities and rapid changeover.

Electronics

The miniaturization of electronic devices has driven demand for ultra-precision manufacturing. Circuit boards, connectors, and semiconductor components require microscopic accuracy.

Global industrial equipment in electronics manufacturing must handle delicate materials while achieving nanoscale precision in increasingly compact designs.

Energy Sector

Renewable energy technologies like wind turbines and solar panels, as well as traditional power generation equipment, rely on precision components for efficiency and longevity.

Global industrial equipment for energy applications must produce components that perform reliably under extreme conditions and varying loads.

Tooling & Molds

The tools, dies, and molds used in manufacturing themselves require precision production. Their accuracy directly influences the quality of all subsequent products.

Global industrial equipment for tooling production enables the creation of complex shapes with the precision needed to replicate parts consistently at scale.

Core Industrial Equipment in Precision Manufacturing

The backbone of precision manufacturing is a diverse array of specialized equipment, each designed for specific operations and materials. Global industrial equipment manufacturers continuously refine these machines to achieve higher precision, greater efficiency, and broader material compatibility.

CNC Machining Centers

Computer Numerical Control (CNC) machining centers represent the cornerstone of modern precision manufacturing. These automated systems interpret digital design files to control machine tools with exceptional accuracy.

Global industrial equipment manufacturers produce various CNC configurations, including vertical machining centers (VMCs), horizontal machining centers (HMCs), and 5-axis machines that can rotate workpieces along multiple axes simultaneously. This versatility allows for complex geometries that would be impossible with manual machining.

Advanced CNC systems incorporate features like thermal compensation, which adjusts for temperature-induced dimensional changes, and adaptive control that modifies cutting parameters in real-time based on sensor feedback. These innovations enable tolerances as tight as ±0.0001 inches (2.5 micrometers) in high-end machines.

Key Capabilities:

Automated tool

changers

Advanced coolantsystems

Precision linearguides

In-processmeasurement

CNC Turning Centers

CNC turning centers specialize in producing cylindrical parts by rotating workpieces while cutting tools shape the material. These machines excel at creating precision shafts, bushings, and other rotational components essential in countless mechanical systems.

Modern turning centers incorporate live tooling capabilities, allowing milling and drilling operations without removing the workpiece, significantly improving precision by eliminating repositioning errors. Global industrial equipment manufacturers have developed multi-spindle turning centers that can produce complex parts in a single setup, reducing production time while maintaining tight tolerances.

Swiss-style turning centers, originally developed for watchmaking, represent the pinnacle of turning precision. These machines hold workpieces with a guide bushing close to the cutting tool, minimizing deflection and enabling exceptional accuracy on small-diameter parts-critical for medical devices and aerospace components.

Common Applications:

Bearing races

Valves and couplings

Electrical Discharge Machining (EDM) Systems

Electrical Discharge Machining (EDM) represents a non-traditional machining method that shapes materials through controlled electrical discharges (sparks) rather than mechanical cutting forces. This technology is invaluable for precision manufacturing of complex shapes in hard materials that would be difficult or impossible to machine with conventional methods.

There are two primary EDM configurations: wire EDM, which uses a thin electrode wire to cut complex shapes, and sinker (or ram) EDM, which employs a shaped electrode to create cavities. Global industrial equipment manufacturers have refined both technologies to achieve remarkable precision, with wire EDM capable of producing cuts as narrow as 0.02mm with tolerances under ±0.001mm.

EDM's unique advantages include the ability to machine hardened materials without causing thermal damage, create intricate internal geometries, and produce fine details with minimal burr formation. These characteristics make it indispensable in tool and die making, aerospace component production, and medical device manufacturing where precision and material integrity are paramount.

EDM Advantages:

Ability to machine extremely hard materials

No mechanical cutting forces to distort delicate parts

Capable of intricate shapes and fine details

Excellent surface finishes achievable

Additive Manufacturing Systems

Additive manufacturing, commonly known as 3D printing, has revolutionized precision manufacturing by building components layer-by-layer from digital models. This approach enables geometries that are impossible with subtractive methods, including complex internal structures, lattice designs, and parts consolidation.

Global industrial equipment manufacturers offer a diverse range of additive technologies tailored to different materials and precision requirements. These include selective laser sintering (SLS), stereolithography (SLA), direct metal laser sintering (DMLS), and binder jetting, each with unique capabilities and applications.

While early additive systems focused primarily on prototyping, modern industrial-grade 3D printers achieve production-quality precision with layer resolutions as fine as 10 micrometers. This has made additive manufacturing viable for end-use parts in aerospace, medical, and other high-precision industries. The technology continues to evolve rapidly, with global industrial equipment innovators pushing the boundaries of speed, material range, and accuracy.

Key Additive Technologies:

DMLS/SLM: Direct Metal Laser Sintering/Melting for metal components

SLA/DLP: Photopolymerization for high-detail plastic parts

SLS: Selective Laser Sintering for thermoplastic components

binder Jetting: For metal and ceramic parts through powder binding

Precision Metrology Equipment

Precision manufacturing would be impossible without the ability to accurately measure components and verify they meet specifications. Metrology equipment provides the critical feedback loop that ensures quality and drives process improvement in precision manufacturing environments.

Coordinate Measuring Machines (CMMs) represent the gold standard for dimensional inspection, using touch probes or optical sensors to collect precise measurements of complex parts. Global industrial equipment manufacturers have developed portable CMMs for shop-floor inspection as well as fixed gantry systems for high-precision laboratory environments that can achieve accuracies in the sub-micrometer range.

Advanced metrology technologies include optical comparators, laser scanners, vision systems, and surface finish analyzers. These tools enable manufacturers to inspect not just dimensions but also surface characteristics, form, and positional relationships between features. Modern metrology systems integrate with CAD models for automated inspection and digital comparison, streamlining the quality control process.

Metrology Technologies:

CMMs: Coordinate Measuring Machines for 3D dimensional analysis

Vision Systems: Non-contact optical measurement for high- speed inspection

Laser Scanners: For capturing millions of data points for complex surfaces

Surface Profilometers: Measuring surface roughness and topography

Precision Manufacturing Processes

Precision manufacturing encompasses a diverse range of processes, each optimized for specific materials, geometries, and tolerance requirements. These processes rely on specialized global industrial equipment designed to achieve and maintain the highest levels of accuracy.

Precision Machining Processes

Milling Operations

Milling involves rotating cutting tools that remove material from workpieces to create complex shapes, slots, pockets, and features. Precision milling utilizes multi-axis CNC machines that can position tools along multiple axes simultaneously.

Global industrial equipment for precision milling incorporates high-speed spindles (up to 60,000 RPM in some cases), rigid machine structures to minimize vibration, and advanced tool holders that ensure minimal runout-critical factors in achieving tight tolerances and fine surface finishes.

Turning Operations

Turning processes rotate the workpiece while stationary cutting tools shape the external and internal surfaces. This process is ideal for cylindrical parts but can also create complex profiles through CNC-controlled tool paths.

Precision turning relies on high-stiffness machine designs, precision spindles with minimal runout, and advanced cutting tools. Modern CNC turning centers integrate live tooling, enabling milling and drilling operations without workpiece repositioning.

Grinding Processes

Grinding uses abrasive wheels to achieve extremely tight tolerances and fine surface finishes. This process is often the final step in precision manufacturing, refining dimensions to their exact specifications.

Types of precision grinding include surface grinding, cylindrical grinding, centerless grinding, and tool and cutter grinding. Global industrial equipment for grinding incorporates sophisticated wheel dressing systems, vibration damping, and precise feed mechanisms to achieve sub-micrometer accuracy.

Non-Traditional Precision Processes

Electrochemical Machining (ECM)

ECM removes material through controlled electrochemical reactions, similar to reverse electroplating. This non-contact process produces complex shapes without thermal or mechanical stress, making it ideal for delicate or heat-sensitive materials.

Global industrial equipment for ECM is particularly valuable in aerospace manufacturing for shaping turbine blades and other complex components from high-strength alloys that are difficult to machine conventionally.

Laser Machining

Laser machining uses highly focused laser beams to cut, drill, or mark materials with exceptional precision. The process generates minimal heat-affected zones and can create extremely small features with high accuracy.

Applications range from micro-drilling in aerospace components to precision cutting of medical devices. Global industrial equipment for laser machining includes fiber lasers, CO2 lasers, and ultrafast lasers, each optimized for specific materials and precision requirements.

Ultrasonic Machining

This process uses high-frequency ultrasonic vibrations (typically 20-40 kHz) to drive abrasive particles against workpieces, removing material through micro-chipping. It is particularly effective for brittle materials like ceramics, glass, and semiconductors.

Ultrasonic machining can achieve intricate shapes with fine details and minimal surface damage. Global industrial equipment for ultrasonic machining continues to evolve, finding increasing applications in electronics manufacturing and advanced material processing.

Precision Manufacturing Process Comparison

Precision Assembly and Finishing Processes

Precision Assembly Techniques

The assembly of precision components requires techniques that maintain the accuracy achieved during manufacturing. Even minor misalignments during assembly can compromise the performance of the final product.

Global industrial equipment for precision assembly includes robotic systems with force feedback, automated alignment systems using vision guidance, and cleanroom assembly stations for contamination-sensitive products like semiconductors and medical devices.

Techniques such as interference fits, adhesive bonding, and laser welding enable the joining of precision components without introducing excessive stress or dimensional changes. In some cases, components are designed for self-alignment during assembly, reducing the need for complex fixturing.

Surface Finishing Processes

Surface finish is critical for many precision components, affecting properties like friction, wear resistance, corrosion resistance, and even optical characteristics. Achieving the required surface quality often involves specialized finishing processes.

These processes include lapping and polishing for extreme flatness and smoothness, chemical etching for surface preparation, and various coating technologies like physical vapor deposition (PVD) and chemical vapor deposition (CVD) for specialized surface properties.

Global industrial equipment for surface finishing incorporates precise process controls to ensure consistency across production runs. Measurement tools integrated into these systems provide real-time feedback, allowing for immediate process adjustments to maintain specifications.

Materials and Advanced Technologies

Precision manufacturing capabilities are closely tied to both the materials being processed and the technologies that enable their transformation. Global industrial equipment must continuously evolve to handle new materials while incorporating emerging technologies that enhance precision and efficiency.

Advanced Materials in Precision Manufacturing

High-Performance Alloys

Titanium, nickel, and cobalt-based superalloys offer exceptional strength-to-weight ratios and temperature resistance. These materials require specialized global industrial equipment capable of handling their high strength and work-hardening characteristics while maintaining precision.

Advanced Composites

Fiber-reinforced polymers and metal matrix composites provide tailored properties but present unique machining challenges due to their heterogeneous structure. Precision manufacturing of composites demands specialized tooling and techniques to prevent delamination and fiber pullout.

Ceramics and Glass

Technical ceramics and specialty glasses offer excellent thermal, electrical, and chemical properties but are extremely brittle. Global industrial equipment for these materials employs non-traditional machining processes to achieve precision without causing fractures.

Metal Matrix Composites

These hybrid materials combine metal matrices with ceramic or carbon reinforcements, creating materials with exceptional stiffness and wear resistance. Their machining requires diamond tooling and specialized cutting strategies available in advanced global industrial equipment.

Smart Materials

Shape memory alloys, piezoelectric materials, and other smart materials respond to environmental stimuli. Their precision manufacturing requires tight control over processing conditions to ensure consistent functional properties.

Nanostructured Materials

Materials engineered at the nanoscale exhibit unique properties. Their precision manufacturing demands global industrial equipment capable of nanometer-level control, enabling applications in electronics, optics, and advanced sensors.

Emerging Technologies Transforming Precision Manufacturing

Digital Twins and Virtual Manufacturing

Digital twin technology creates virtual replicas of physical components, processes, and even entire production lines. These digital models enable manufacturers to simulate, analyze, and optimize production processes before physical implementation.

When integrated with global industrial equipment, digital twins provide real-time insights into machine performance and process variables. This allows for predictive maintenance, process optimization, and rapid troubleshooting without disrupting production.

Virtual manufacturing environments enable engineers to test different machining strategies, tool paths, and material properties in a risk-free digital space. This reduces development time, minimizes material waste, and accelerates the implementation of new precision manufacturing processes.

Artificial Intelligence and Machine Learning

AI and machine learning algorithms are increasingly integrated into global industrial equipment to optimize precision manufacturing processes. These systems analyze vast amounts of production data to identify patterns and correlations beyond human capability.

Applications include adaptive control of machining processes, predictive quality control, and automated defect detection. By continuously learning from production data, these systems can make real-time adjustments that maintain optimal precision and efficiency.

Industrial Internet of Things (IIoT)

The IIoT connects global industrial equipment through sensors and network connectivity, enabling seamless data collection and communication across manufacturing systems. This interconnectedness provides unprecedented visibility into production processes.

In precision manufacturing, IIoT enables real-time monitoring of critical process variables, remote diagnostics, and coordinated operation of multiple machines. This results in improved process stability, faster issue resolution, and more consistent part quality.

Quality Control in Precision Manufacturing

Quality control is the cornerstone of precision manufacturing, ensuring that every component meets exacting specifications. This rigorous process relies on advanced measurement technologies, statistical analysis, and integration with global industrial equipment to maintain consistent quality.

Principles of Precision Quality Control

Total Quality Management

This holistic approach embeds quality considerations throughout the entire manufacturing process, from design to final inspection. It emphasizes employee involvement, process standardization, and continuous improvement to prevent defects rather than simply detecting them.

Statistical Process Control (SPC)

SPC uses statistical methods to monitor and control manufacturing processes. By analyzing process data in real-time, manufacturers can detect variations before they result in out-of-specification parts. Modern global industrial equipment often includes built-in SPC capabilities for immediate feedback.

Acceptance Sampling

In high-volume precision manufacturing, 100% inspection may be impractical. Acceptance sampling uses statistical techniques to determine the appropriate sample size and acceptance criteria, balancing inspection efficiency with quality assurance.

Traceability Systems

Comprehensive traceability enables manufacturers to track every component throughout production, including materials, processing steps, operators, and inspection results. This is critical for root cause analysis when quality issues arise and is increasingly required by regulatory standards

Advanced Inspection Techniques

3D Scanning

Laser and structured light scanners capture millions of data points to create precise 3D models for comparison against CAD designs, enabling comprehensive dimensional analysis.

Automated Vision Inspection

High-resolution cameras and advanced algorithms perform rapid, consistent inspection of surface features, patterns, and dimensions, often integrated directly with production lines.

Metallographic Analysis

Microscopic examination of material structures ensures proper heat treatment, detects internal defects, and verifies material properties critical for performance.

Coordinate Measuring

CMMs and portable measuring arms use touch probes or laser sensors to verify complex geometries with sub-micrometer accuracy, essential for critical components.

International Standards and Certifications

Precision manufacturing operates within a framework of international standards that define quality requirements, measurement practices, and process controls. These standards ensure consistency across global industrial equipment and production facilities.

ISO 9001

The international standard for quality management systems, specifying requirements for establishing, implementing, maintaining, and improving a quality management system.

Applicable to all types of organizations and provides a framework for consistent quality across global industrial equipment and manufacturing processes.

ISO 13485

Specifically addresses quality management systems for medical device manufacturers, with rigorous requirements for design control, risk management, and traceability.

Ensures that precision manufacturing of medical components meets regulatory requirements for safety and effectiveness.

AS9100

Quality management system standard for the aerospace industry, building on ISO 9001 with additional requirements specific to aviation, space, and defense products.

Addresses the unique quality and safety considerations in aerospace precision manufacturing, recognized by major aerospace primes worldwide.

Additional standards relevant to precision manufacturing include ISO 10360 for coordinate measuring machines, ISO 1302 for surface texture symbols, and ISO 2768 for general tolerances. Compliance with these standards ensures that measurements and specifications are interpreted consistently across global industrial equipment and supply chains.

Many precision manufacturing facilities also pursue specialized certifications such as ITAR registration for defense-related work, Nadcap accreditation for aerospace special processes, and ISO 14001 for environmental management, demonstrating commitment to comprehensive quality and responsibility.

Future Trends in Precision Manufacturing

The precision manufacturing industry continues to evolve rapidly, driven by advancements in technology, materials science, and global industrial equipment capabilities. These innovations promise to push the boundaries of what's possible in terms of precision, efficiency, and application diversity.

Micro and Nano Manufacturing

As technology continues to miniaturize, precision manufacturing is advancing into the micro and nano realms. This trend is driven by demands from electronics, medical devices, and emerging fields like micro-robotics and nanotechnology.

Global industrial equipment manufacturers are developing systems capable of positioning tools and workpieces with nanometer-level accuracy. Techniques such as focused ion beam machining, atomic layer deposition, and nanoimprint lithography enable the creation of structures with features smaller than 100 nanometers.

These capabilities open new frontiers in fields like quantum computing, where precise control of atomic structures is required, and in medical applications such as targeted drug delivery systems and microscopic sensors for minimally invasive procedures.

Smart Factories and Digital Integration

The ongoing transition to Industry 4.0 is transforming precision manufacturing facilities into highly connected, data-driven smart factories. These environments leverage advanced sensors, artificial intelligence, and the Industrial Internet of Things (IIoT) to optimize every aspect of production.

Global industrial equipment is increasingly designed with built-in connectivity and intelligence, enabling seamless integration into these digital ecosystems. Machine learning algorithms analyze production data to predict maintenance needs, optimize cutting parameters, and even anticipate quality issues before they occur.

Digital threads connect design, simulation, production, and inspection processes, ensuring complete traceability and enabling rapid design iterations. This integration reduces time-to-market while maintaining the highest precision standards.

Sustainability in Precision Manufacturing

Environmental sustainability is becoming increasingly central to precision manufacturing, driving innovations in energy efficiency, material usage, and waste reduction. Global industrial equipment manufacturers are responding with machines designed for minimal environmental impact.

Energy-efficient motors, regenerative braking systems, and optimized hydraulic and pneumatic components reduce the energy footprint of precision manufacturing equipment. Advanced cooling systems minimize water usage, while improved chip management systems enhance material recovery and recycling.

Sustainable manufacturing practices also include lightweighting components to reduce material consumption, developing more efficient machining processes that minimize waste, and implementing closed-loop manufacturing systems that reuse and recycle materials.

These efforts not only reduce environmental impact but often improve efficiency and reduce costs, creating a win-win scenario for manufacturers and the planet.

Converging Technologies: Hybrid Manufacturing

A significant trend in precision manufacturing is the integration of additive and subtractive processes into hybrid systems. These versatile machines combine the design freedom of 3D printing with the precision finishing capabilities of CNC machining, offering unprecedented manufacturing flexibility.

Design Freedom

Hybrid systems enable complex internal geometries through additive manufacturing while ensuring precise external dimensions through subtractive finishing in a single setup.

Reduced Lead Times

Eliminating multiple setups and transfers between machines significantly reduces production time while improving accuracy by maintaining a single coordinate system.

Material Innovation

Hybrid systems support multi-material manufacturing, enabling components with graded material properties optimized for specific performance requirements.

Global industrial equipment manufacturers are at the forefront of this hybrid revolution, developing systems that seamlessly integrate additive processes like laser metal deposition with subtractive capabilities such as high-speed milling. These machines are finding applications in aerospace, medical, and tooling industries where complex geometries and precision go hand in hand.

Frequently Asked Questions

What core technologies enable industrial equipment to achieve micron-level precision in manufacturing robust components?

Advanced industrial equipment leverages a synergy of technologies, including computer numerical control (CNC) systems with real-time feedback loops, high-resolution linear encoders (often with 0.1μm accuracy), and servo motors with nanosecond response times. Additionally, thermal compensation systems counteract temperature-induced expansion/contraction, while adaptive control algorithms adjust tool paths dynamically based on sensor data-ensuring consistent precision even when machining high-strength materials like alloy steels or titanium.

How does industrial equipment handle the unique challenges of machining robust materials (e.g., hardened metals, composites) without compromising precision?

Specialized equipment integrates high-torque spindles (up to 60,000 RPM for hard metals) paired with ultra-durable cutting tools (e.g., cubic boron nitride or polycrystalline diamond inserts). Coolant systems with precise delivery (via micro-jets) reduce heat-induced tool wear and material deformation. For composites, adaptive feed-rate control modulates speed based on fiber orientation, preventing delamination while maintaining tight tolerances (typically ±0.001mm for critical surfaces).

What role do automated inspection systems play in industrial equipment for precision manufacturing?

In-line inspection modules, such as coordinate measuring machines (CMMs) and 3D laser scanners, are integrated into production lines to verify dimensions post-machining. These systems operate in real time, comparing measurements to CAD models and triggering adjustments to upstream equipment (e.g., tool offsets) if deviations exceed thresholds. This closed-loop feedback ensures 100% traceability and reduces scrap rates to less than 0.5% in high-volume production.

How is industrial equipment optimized for energy efficiency while maintaining high throughput in precision manufacturing?

Modern equipment uses variable-frequency drives to match motor output to load demands, reducing idle energy consumption by up to 30%. Regenerative braking systems capture excess energy during deceleration, feeding it back into the facility grid. Additionally, lightweight yet rigid machine frames (using materials like cast iron with reinforced ribbing) minimize energy loss from vibration, while smart scheduling software optimizes equipment utilization to reduce unproductive runtime.

What advancements in industrial equipment have improved the repeatability of manufacturing robust components?

Recent innovations include direct-drive technology (eliminating backlash from gear systems), self-calibrating sensors that auto-correct for drift, and machine learning algorithms that predict and compensate for wear in cutting tools. Additionally, modular fixturing systems with sub-micron positioning accuracy ensure consistent part clamping, while thermal symmetry in machine design reduces temperature-related variations. These advancements have pushed repeatability to within ±0.0005mm for critical dimensions in aerospace and automotive components.

How does industrial equipment adapt to rapid design changes in precision manufacturing of custom robust components?

Flexible manufacturing systems (FMS) with plug-and-play tool changers (capable of swapping 50+ tools in under 10 seconds) enable quick reconfiguration for new part designs. Cloud-connected CNC controllers allow remote programming and real-time adjustment of tool paths, while digital twins simulate production processes to identify optimization opportunities before physical machining. For low-volume, high-mix production, adaptive machining systems use in-process metrology to automatically adjust parameters based on part-to-part variations, ensuring compliance with custom specifications without manual intervention.