Choose a Manufacturing Service

Our manufacturing processes and material choices offer flexible solutions tailored to your needs at every stage of product development. From single prototypes to large-scale production, we are your trusted manufacturing partner, committed to delivering high-quality components.

Learn more about our capabilities:

Compare our Digital Manufacturing Services

| Service | Lead Times | Materials | Tolerances |

| Injection Molding | 7-30 days | Thermoplastic and Thermoset | +/- 0.003 in |

| CNC Machining | 7-30 days | Metals and Plastics | +/-0.002 in |

| Wire EDM | 7-30 days | Metals | +/-0.002 in |

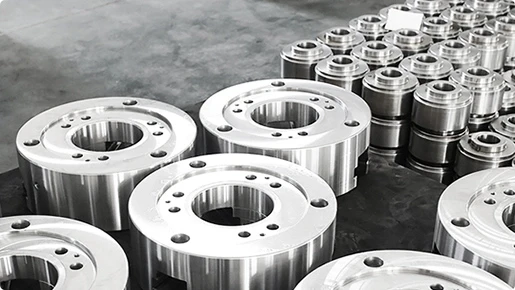

CNC lathe parts high precision, high concentricity

Make complex geometric shapes

Provides a wide range of plastic and metal materials processing services

Strictly follow the first part inspection to ensure the quality of the parts

FAQ

CNC Machining : Dynamic Deformation and Vibration Coupling in Thin-Wall Component Processing

Problem Description: During high-speed CNC milling of aerospace thin-wall structural components (wall thickness <2mm), complex dynamic coupling vibrations occur in the workpiece-tool-machine tool system, leading to chatter, periodic surface ripples, and severe dimensional accuracy deviations.

Solution: Establish a multi-body dynamics model and identify system natural frequencies through modal analysis. Employ variable helix angle CNC milling cutters (30°-45° gradient) to disrupt the periodicity of regenerative chatter. Implement adaptive feed control based on spindle current feedback for real-time CNC feed rate adjustment. Utilize harmonic dampers or dynamic vibration absorbers to provide 20-30dB vibration attenuation in critical frequency bands. Optimize the CNC clamping system using vacuum chuck + mechanical clamp composite fixation to increase system damping ratio above 0.08. Predict machining deformation through finite element simulation and establish compensation algorithms for CNC operations. Implement variable parameter CNC machining: rough machining with high feed-low speed, precision machining switching to small depth-high speed mode, achieving surface roughness control within Ra0.4μm in CNC processing.

EDM Wire Cutting : Multi-axis Linkage Trajectory Optimization and Discharge Stability in Complex Cavities

Problem Description: When EDM wire cutting complex irregular cross-sections like aero-engine blade tenon slots, improper five-axis linkage trajectory planning causes uneven discharge gaps, severe local burning, difficult geometric accuracy assurance, and Ra values exceeding 1.6μm in EDM wire cutting operations.

Solution: Establish B-spline-based five-axis tool path optimization algorithm ensuring curvature continuity in EDM wire cutting. Adopt adaptive gap control system monitoring discharge status through voltage-current characteristic curves, dynamically adjusting servo feed speed in EDM wire cutting. Implement layered discharge strategy: establish 3D electric field simulation model predicting discharge density distribution in different regions, applying reduced power parameters (30% pulse width reduction) for concave areas in EDM wire cutting. Optimize working fluid circulation system with spiral nozzle arrays ensuring >85% flow velocity uniformity in complex cavities during EDM wire cutting. Introduce machine learning algorithms building discharge parameter self-optimization models based on historical EDM wire cutting data. Employ composite electrode wire (tungsten-molybdenum alloy) improving tensile strength to 1200MPa for EDM wire cutting. Through intelligent process parameter matching in EDM wire cutting, geometric accuracy can be improved to ±0.005mm with surface quality reaching Ra0.8μm.

Injection Molding : Non-isothermal Crystallization Kinetics and Molecular Orientation Control in Crystalline Polymers

Problem Description: Semi-crystalline polymers (such as POM, PA66) in complex geometric injection molding products exhibit uneven spherulite sizes and varying molecular chain orientations, causing anisotropic shrinkage, internal stress concentration, microcracks, and stress cracking during long-term use in injection molding applications.

Solution: Establish Avrami-Ozawa non-isothermal crystallization kinetics model calculating spherulite nucleation and growth processes under different cooling rates in injection molding. Design gradient cooling system: injection molding cavity temperature with zone control, maintaining 8-12°C temperature difference from gate to end, achieving uniform crystallization rate in injection molding. Optimize injection molding parameters: employ multi-stage speed control with high-speed injection (300mm/s) during filling stage reducing molecular chain relaxation time, low-pressure long-duration (12-15s) holding stage promoting stress release in injection molding. Introduce nucleating agents (talc 0.1-0.3%) refining spherulite size to 5-10μm in injection molding. Implement vibration-assisted injection molding, applying 20-50Hz low-frequency vibration in crystallization temperature range disrupting large spherulite formation. Optimize process windows through polarized light microscopy and DSC analysis, establishing crystallinity-performance relationship database for injection molding. Finally, internal stress can be reduced by 60%, injection molding product warpage controlled within 0.02%, and impact strength improved by 40%.

Industries We Serve

Automobile manufacturing

Semiconductor

Aviation

Electronic

Mechanical

New Energy

Let's create extraordinary together

At Abismould, we specialize in CNC turning services for precision components. From straightforward to intricate designs, our tailored non-standard parts CNC turning solutions deliver exceptional results. Reach out today to explore your project and discover how we can support your objectives.